Techno Machines India

HSIIDC Kundli Sonipat HR-131028 (India)

+91-971-162-8382

+91-971-162-8373

HSIIDC Kundli Sonipat HR-131028 (India)

+91-971-162-8382

+91-971-162-8373

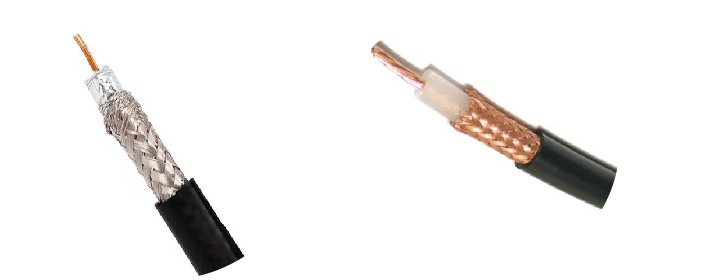

This machine adopts advanced programmable and frequency Conversion control technology, microcomputer, and has the characteristics of stepless speed regulation, high-speed knitting, full fault display, low noise, high reliability, high precision, and high strength. Using a specific weaving method, the spindle has an automatic tension control mechanism, adjustable tension, and has an automatic lubrication system and a safety silencing shield. This machine can not only braid copper wire, but also other metal wires such as aluminum-magnesium alloy wire and stainless-steel wire. The spindle volume of this braiding machine is the largest among all braiding machines.

| Model | TM-24S |

|---|---|

| Braiding Form | 2 Stacks of 2 (one over other) |

| Braiding Direction | Vertical |

| Number of Bobbin | 24 (12 Upper and 12 Lower) |

| Machine Speed | 0-100 rpm |

| Braided wire material | Aluminum magnesium alloy wire, Copper Wire, Stainless Steel Wire. |

| Max Braiding Outer Diameter | 24 mm |

| Bobbin Size (Capacity) | ф75×ф22×71×100 (Outer diameter×Barrel diameter ×Inner width×Outer width) |

| Pitch range | 13.4~135mm |

| Pitch adjustment model | Gear adjustment with full set of pitch gears |

| Traction model | Wheel Traction |

| Main Motor Power | 2.2Kw |

| Lubrication method | Oil Pump Automatic Oil filling lubrication |

| Payoff / Take-up spool size | 500 to 800 mm |

| Protection cover | Sealed box type protective cover, front and rear doors can be opened |

| Control | Using the special computer controller of sanp knitting machine and delta 1.5KW frequency converter, it can automatically set the rotation speed, automatically count the meter, automatically inject oil, and automatically alarm for wire breaking, cable breaking, tape breaking, oil shortage, etc. |

| Noise | ≤85dB |

| Machine Size | 1700×1700×2500mm(L×W×H) |

| Weight | Approx. 1200Kg |